Every year, thousands of children accidentally get into medicines they shouldn’t. It’s not because they’re curious little explorers-it’s because many medicine bottles still look like toys. But there’s a reason those caps are so hard to twist: child-resistant packaging. It’s not perfect, but it’s saved hundreds of thousands of lives since it became law in 1970.

What Exactly Is Child-Resistant Packaging?

Child-resistant packaging, or CR packaging, isn’t meant to be child-proof. That’s a common mistake. No container can guarantee a curious toddler won’t get inside. Instead, CR packaging is designed to make it hard enough for kids under five to open within a few minutes-enough time for an adult to notice and intervene. The U.S. Consumer Product Safety Commission (CPSC) set the standard under the Poison Prevention Packaging Act (PPPA) of 1970. Before that, over 5,000 children died from accidental poisonings between 1961 and 1966. Today, thanks to these caps, pediatric poisoning deaths have dropped by 45% since 1974. That’s nearly 900,000 preventable incidents every year. The rules are strict. To pass, a container must block at least 85% of children aged 42 to 51 months from opening it within 10 minutes. After that, those same kids get a 5-minute demo to learn how it works. If they still can’t open it, the design passes. For adults, especially seniors, at least 90% of people aged 50 to 70 must open and re-close the cap within 5 minutes. That’s the balance: safety for kids, usability for grown-ups.How Do These Caps Actually Work?

Not all safety caps are the same. The most common type is the push-and-turn cap. You press down while twisting-two motions at once. That’s tough for small hands, which usually only know how to twist. Other designs include squeeze-and-turn caps, where you have to compress the cap while turning it, or interlocking mechanisms that require you to slide and twist simultaneously. These caps are made from high-density polyethylene (HDPE) or polypropylene, materials strong enough to handle repeated use without breaking. The threading inside is precision-engineered so the cap won’t strip after 50 openings. Some newer versions even have built-in locks that click into place after closing. But not every medicine type is easy to package. Solid pills in bottles? Easy. CR caps work on them 97% of the time. Liquid medications? Much harder. Nearly 39% of non-compliant packaging cases involve liquids. Why? Because bottles leak if the seal isn’t perfect, and kids can sometimes squeeze the bottle hard enough to open it. Nasal sprays are the toughest. The CPSC says the pump itself isn’t child-resistant-even if it’s crimped onto the bottle. The solution? Specialized CR spray pumps that require a two-step action: unlock the nozzle, then press. Only 22% of nasal sprays met the standard before these innovations.Who Benefits? Who Struggles?

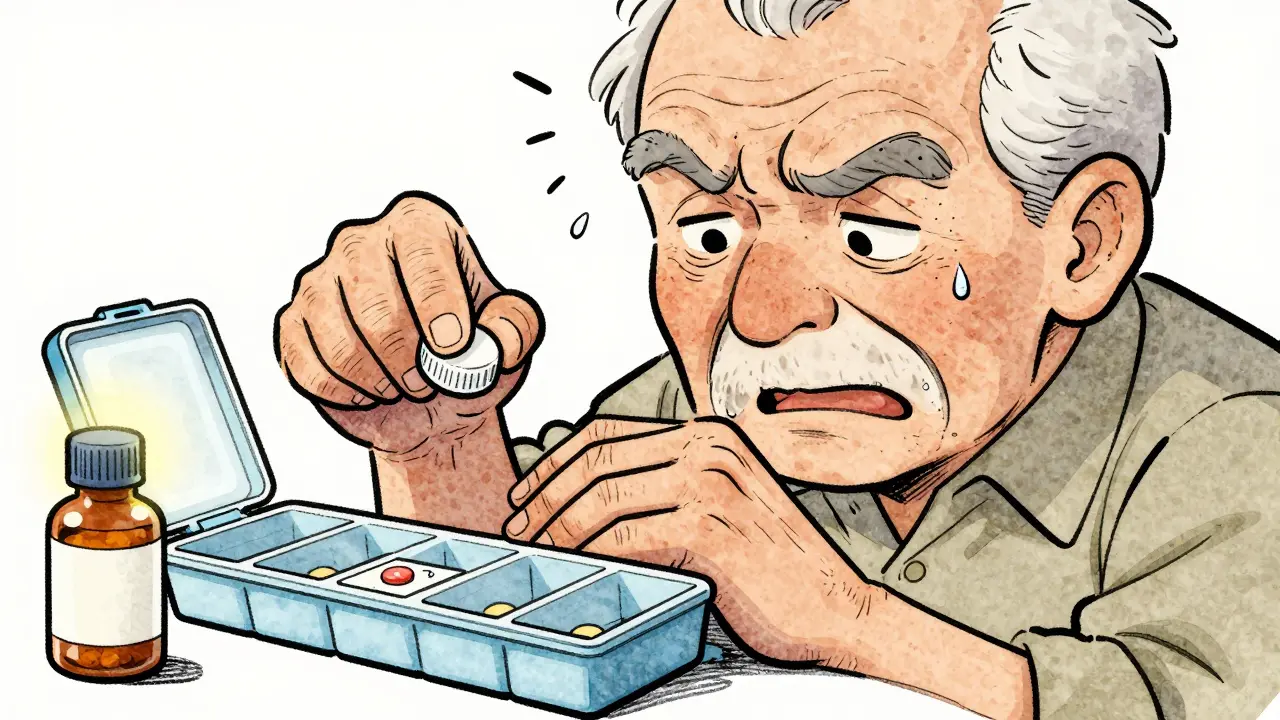

CR packaging protects kids. But it doesn’t always help everyone else. Seniors with arthritis, tremors, or limited hand strength often struggle. A 2022 Arthritis Foundation survey found 68% of people with hand impairments had trouble opening CR caps. Some need up to 10 pounds of force-way above the 5-pound recommendation for senior-friendly designs. On Reddit, nurses share stories: “My 78-year-old patient cried trying to open her blood pressure pill bottle. She gave up and left it open.” That’s dangerous. When people can’t open their meds, they leave caps off. And that’s how kids get in. But things are improving. New designs like Blisterpak’s Easy-Open system have earned 4.2 out of 5 stars from over 1,200 users. One reviewer wrote: “Finally, a cap my 70-year-old mom can open without help.” These caps use a side-release mechanism-no twisting needed. Just press and pull.

What Medicines Require CR Packaging?

Not everything needs a safety cap. The CPSC mandates CR packaging for about 30 categories of hazardous products. That includes:- All prescription medications (including Schedule II-V controlled substances)

- Over-the-counter drugs with specific ingredients like acetaminophen, ibuprofen, iron, or aspirin above certain doses

- Products containing 0.08 mg or more of imidazoline (found in some nasal decongestants)

- Pesticides, household cleaners, and certain cosmetics

- Nicotine-containing e-cigarette refill pods (since 2016)

The Hidden Problem: Improper Re-Closing

Here’s the scary part: most child access incidents don’t happen because the cap was broken. They happen because someone opened it, didn’t close it right, and walked away. CPSC data shows 73% of cases in 2022 involved improper re-closure. A parent thinks they snapped the cap shut. But if they didn’t push down hard enough while turning, it didn’t lock. The cap looks closed-but it’s not. Studies show CR effectiveness drops by 15% after the first opening. That’s why pharmacists now train patients: “Don’t just twist. Push down while you turn. You should hear a click.” And sometimes, the cap itself fails. Consumer Reports tested 30 different brands in 2023. CVS Health’s generic CR caps failed child resistance tests 22% of the time. Manufacturer-specific caps? Only 8% failed. Brand matters.

What Happens If a Company Doesn’t Comply?

Pharmaceutical companies can’t just slap on any cap and call it good. Every CR packaging design must be tested by a CPSC-accredited lab. The cost? $8,500 to $15,000 per design. They must also document compliance in their FDA submission under Module 3.2.P.7. The exact wording required: “We verify in this submission that the following package (or packages) meet CPSC’s standards under 16 CFR 1700.” If they skip this? FDA warning letters. Fines up to $100,000 per violation. And if a child gets sick because of a non-CR bottle? That’s not just a fine-it’s a lawsuit. Even veterinarians aren’t exempt. A 2022 survey found 44% of vet clinics were giving out meds in non-CR bags or envelopes. That’s illegal if the drug requires CR packaging. The CPSC doesn’t care if it’s for a dog. If a child could get to it, it must be safe.What’s Next for Safety Caps?

The future of CR packaging isn’t just about harder caps-it’s about smarter ones. In January 2023, Aptar Pharma launched the first FDA-cleared connected safety cap: SmartDose. It looks like a regular CR cap, but inside is a Bluetooth chip that records every time it’s opened. If a child gets into the bottle, the parent gets a notification on their phone. The system is 99.2% accurate. Regulators are also expanding the list. In 2023, the CPSC proposed new rules requiring CR packaging for all THC edibles with more than 2 mg of THC per serving. Why? Because kids are eating them like candy. And the aging population is pushing innovation. Over 60% of new CR packaging patents since 2018 include senior-friendly features. Designs are now being tested with real seniors-not just lab volunteers. The global CR packaging market is projected to hit $4.87 billion by 2028. That’s not just business-it’s public health.What Should You Do?

If you have kids at home-or even just visit a house with kids-here’s what to do:- Always re-close CR caps properly: push down and twist until you hear or feel a click.

- Store meds up high, out of sight. Not on the counter, not in the purse.

- Don’t rely on the cap alone. Use locks, cabinets, or high shelves.

- If you or someone you care for has trouble opening caps, ask your pharmacist for a senior-friendly version. They can request non-CR packaging with your signed consent.

- Never transfer pills to unmarked containers like pill organizers or candy jars. That’s how accidents happen.

Are child-resistant caps really effective?

Yes, but not perfectly. They prevent at least 85% of children under five from opening them within 10 minutes, according to CPSC testing. Since 1970, they’ve reduced pediatric poisoning deaths by 45%. But they’re not foolproof-73% of incidents happen because the cap wasn’t properly re-closed.

Can seniors open child-resistant caps?

Many can, but not all. CPSC requires that at least 90% of adults aged 50-70 open and re-close the cap within 5 minutes. But real-world data shows 68% of people with arthritis struggle. Newer designs like side-release or push-button caps are easier. Ask your pharmacist for senior-friendly options if you’re having trouble.

What medications don’t need child-resistant packaging?

Some OTC medications don’t require CR packaging if they contain low doses of active ingredients. Examples include low-dose aspirin (under 81 mg per tablet), certain antacids, and some topical creams. Also, medications for institutional use (like hospitals) or those dispensed in unit-dose blister packs without a secondary CR overcap don’t always need CR caps. Always check the label.

Can I request non-child-resistant packaging?

Yes, but only if you sign a written statement acknowledging the risks. Pharmacists are required to offer this option to patients who can’t open CR caps due to disability or age. The pharmacy must document your request and provide a warning label on the bottle stating it’s not child-resistant. Never use this option if children are present in your home.

Do all countries use child-resistant packaging?

Most developed countries do. The U.S., EU, Canada, Australia, and Japan all have strict CR packaging laws. Brazil and India implemented similar rules in 2021 and 2022. The standards vary slightly-some require stronger senior accessibility-but the goal is the same: protect children while keeping medicine accessible to adults.